| |

|

|

THERMAL CONDUCTIVITY |

|

|

| |

| C-THERM TCi |

| |

Principles of Operation

Modified Transient Plane Source Technique

The C-Therm TCi Thermal Conductivity Analyzer employs the Modified Transient Plane Source (MTPS) technique in characterizing the thermal conductivity and effusivity of materials. It employs a one-sided, interfacial heat reflectance sensor that applies a momentary constant heat source to the sample. Typically, the measurement pulse is between 1 to 3 seconds. Thermal conductivity and effusivity are measured directly, providing a detailed overview of the heat transfer properties of the sample material. |

| |

|

| |

| HOW IT WORKS |

| |

|

| |

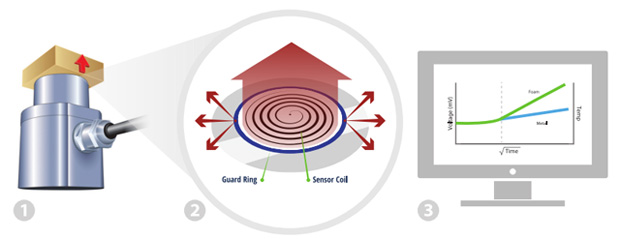

| (1) A known current is applied to the sensor's spiral heating element, providing a small amount of heat. (2) A guard ring surrounds the primary sensor coil to support a one-dimensional heat transfer into the sample. The applied current results in a rise in temperature at the interface between the sensor and the sample, which induces a change in the voltage drop of the sensor element. (3) The rate of increase in the sensor voltage is used to determine the thermal properties of the sample. The voltage is factory-calibrated to temperature. The thermal conductivity is inversely proportional to the rate of increase in the temperature at the point of contact between the sensor and the sample. The voltage is used as a proxy for temperature and will rise more steeply when lower thermal conductivity materials (e.g. foam) are tested. Conversely, the voltage slope will be flatter for higher thermal conductivity materials (e.g. metal). With the C-Therm TCi, results are reported in real-time making thermal conductivity measurement fast and easy. |

| |

|

| |

| For more information click here... |

|

|

|

|

| |

|